General Info

General Info

Different Lab Testing & Analysis & Their Principles

- Coating Thickness: - The coating thickness on magnetic substrate is determined by means of an electronic probe placed on the coating & developing an electromagnetic field, which is the function of the distance between the probe and the base metal. It is measures in m (micron). The coating thickness on non-magnetic substrate determined by an electrical probe. Placed on the surface coating and & producing eddy current in the base metal. The variation of amplitude between the probe & base metal is the thickness of the coating.

- Solvent Rubbing Test: - This test defines the degree of baked film by the solvent (MEK).

- Cross Cut Adhesion: - The cross cut test estimate the adhesion of the coating to the substrate.

- Gloss: - Gloso-meter is used for the measurement of Gloss. Reflecto-meter operate in accordance with the reflection principle i.e. Reflection caused by the specimen is measured in accordance with the internal standard. It certain at 20°, 60°, and 85°.Basically by Gloso-meter gloss is measure at 60°.

- PENCILE HARDNESS TEST: - This method defines procedure for testing the relative hardness of coating the hardest led which does not penetrate the coating determines the hardness. Normally H, 2H, 3H, F, HB, 3H, 2H Led is used for the testing.

- SRATCH TEST: - This method defines the resistance to the scratching the coating used on the surface by scratch test using the weight, that how much weigh can a coated surface can resist.

- T-BEND TEST: - It checks the adhesion on Zinc coating on the base material along with the paint, & adhesion check. Ultimately we can say for the flexibility of paint we used T-bend test.

- IMPACT TEST: - The reverse impact test defines the impact resistance of the coating, Paint and other. The reverse impact test is measured to check the reverse impact on the coated surface 80 lbs weight is used to check the reverse impact Basically the adhesion of paint during Reverse Impact or reverse adhesion falling weight gives the result of resistivity of the paint.

- CUPPING TEST: - This test checks the durability of the coating films as well as substrate in it.

- FINAL COLOUR TEST: - colour computer can measure final Colour difference.

Colour is a sensation received by the activation of retina of the eye.

By the help of colour computer we can calculate various wavelength of the light. These are as under.

L = shade is Lighter or Darker.

A = shade is Redness or Greenness.

B = Shade is Blueness or Yellowness.

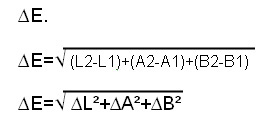

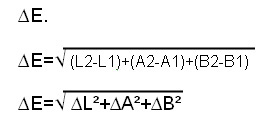

Suppose standard shade on having the value L1, A1 & B1 and the Sample L2, A2, & B2. Hence we can measures the colour Difference i.e.

If ∆E is less than 0.5 it cannot be distinguished by the human naked eye.

If ∆L is + ve = sample is Lighter.

If ∆L is - ve = sample is Darker.

If ∆A is + ve = sample is Redder.

If ∆A is – ve = sample is Greener.

If ∆B is + ve = sample is Yellow.

If ∆B is – ve = sample is Blue.

General Info

General Info